Ready for easyroll©

Available in 100% electric version

The solution to your

problem… and more

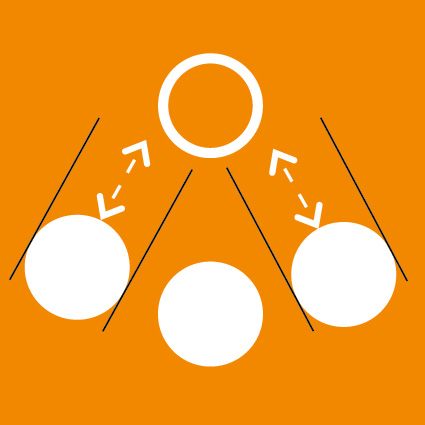

3 rollers

Capacity 0.5-40 mm (steel S235)

Usable length: 1-6 m

IF YOU HAVE A SHORTAGE OF QUALIFIED OPERATORS AND YOU ARE LOOKING FOR A MACHINE THAT OFFERS SUPERIOR PERFORMANCE, THE R3 THREE-ROLLER SHEET BENDING MACHINE (SYMMETRICAL THREE-ROLLER ARCHITECTURE PROVIDING DOUBLE PREBENDING WITHOUT TURNING THE SHEET OVER) IS SURE TO SATISFY YOUR NEEDS.

Its ability to roll thin materials without laminating the sheet and its prebending performance with a limited residual flat edge are thanks to its special symmetric architecture. Thanks to its linear guide system (specific angle) and its bearing system with bronze rings, we guarantee high-quality rolling with regard to sheet edge straightness and cylindrical roundness.

The R3 sheet bending machine is especially recommended for:

- working on single items with high added value (in combination with the Easyroll control system)

- thin sheets and decorative work (design)

- operations with strict requirements concerning geometry (cylindrical roundness, straightness, etc.) and repeatability.

- Work on conical parts

- 3D parts (honeycomb, extruded, perforated)

- materials that are difficult to grasp (with the Easyroll control system and its predictive material database): aluminium, stainless steel, Hardox, etc.

The R3 3 roller bending machine has almost unlimited scope. Its wide capacity range, from 0.5 to 40 mm thickness and up to 6 m length, makes it versatile enough to use for almost any application.

R3 Next Gen: a new standard to support your industrial challenges and evolution

- Architecture with 3 independent powered rollers mounted on bronze rings

- Connectivity 4.0 for remote operation and interfacing with your organisation

- Easyroll ready as standard (all of our machines are upgradeable by a Plug & Play console change without other modifications)

- Easyroll: our patented software! Like a GPS to guide you through the bending process. Updates and new versions are provided free of charge.

- AIR: Artificial intelligence for Roll bending machine, an extension of Easyroll since V4

- 100% electric R3e version is possible up to 10 mm or Danfoss-equipped hydraulics (100% progressive movements).

R3 What are the advantages of SHEET BENDING

MACHINE with three symmetric roller technology

01

Three powered rollers

One motor (gearmotor) per roller as standard. Our machines have been equipped with Danfoss motors for over 35 years. The rotation of the rollers is factory-synchronised by a hydraulic system that prevents any variation over time.

Benefits: maximum torque, optimised efficiency, synchronised speed, reliability.

Note: Our competitors only have one or two powered rollers as standard.

02

Special architecture: design for identical roller diameters

To guarantee the best performance in terms of bending and deformation of the part, we have three rollers of identical diameter.

The benefits: perfect geometry in the bending profile and better machine capacity.

Note: Our competitors’ lateral rollers have much smaller diameters -> reduced capacity

-> up to 30% additional bending.

03

Linear guide system

An incredibly useful technology, with no friction and excellent performance in all operating modes: cylindrical and conical rolling. It’s also a strategic choice for optimised prebending (on three- and four-roller machines)

Benefits: maximum efficiency of the hydraulic power, no wear.

Note: The planetary guide system used by our competitors is a low-cost solution

-> up to 30% loss of power and additional wear.

04

Bronze Bearing Technology

All of our machines are equipped with bronze bearings that accept high loads during rolling operations.

This technology is unrivalled in terms of both its capabilities and its longevity! Greasing is centralised and requires no maintenance.

Note: Our competitors use roller bearings (more economical, but unable to withstand heavy loading).

05

Architecture for cone rolling

The frame design is optimised for easy cone rolling.

The three-roller architecture is best suited to this type of part. The cone must be formed by symmetric bending with a specific tilt of the lower rollers. In conjunction with the Easyroll control system, cones can even be created automatically.