Ready for easyroll©

Available in 100% electric version

The solution to your problem…

and more

- 4 rollers

- Capacity: 8-50 mm (steel S235)

- Usable length: 1-5 m

Created in the 1980s alongside similar types of hydraulic machine, the R4C four-roller sheet bending machine was developed especially to handle thick materials, always keeping the plate clamped between two rollers.

Today it’s the most popular machine on the market, largely because others have been considerably simplified, often to create a low-cost machine with just one or two powered rollers, alignment control by torsion bar, planetary guide system, etc. We didn’t follow that trend because it diminished the performance of those machines.

That’s why the R4C sheet bending machine is still a four-roller machine that makes no compromises: four powered rollers with linear guide system for top performance (prebending, power, etc.) and agility in all situations. We have equipped it with an innovative clamp control technology to limit the effects of lamination of the plate (pressure and position control).

Our four-roller technology is especially recommended for:

- thick materials (above 20 mm)

- mass-produced parts

- tanks with multiple radii

- integration into a global process: loading table, evacuation, welding, etc.

It is not recommended for use on very thin sheets or for cone rolling; the R3 performs well for those purposes.

R4 Next Gen: a new standard to support your industrial challenges and evolution

- Architecture with four independent powered rollers mounted on bronze rings

- Connectivity 4.0 for remote operation and interfacing with your organisation

- Pressure and position control of the clamping rollers to limit deformation and marking of thin sheets

- Use with three or four rollers to take advantage of each of the technologies (two machines in one!)

- Easyroll ready as standard (all of our machines are upgradeable by a Plug & Play console change without other modifications)

- Easyroll: our patented software! Like a GPS to guide you through the bending process. Updates and new versions are provided free of charge.

- AIR: Artificial intelligence for Roll bending machine, an extension of Easyroll since V4

What are the advantages of the R4 Next Gen sheet bending machine with four symmetric roller technology

01

Four powered roller

One motor (gearmotor) per roller as standard. Our machines have been equipped with Danfoss motors for over 35 years. The rotation of the rollers is factory-synchronised by a hydraulic system that prevents any variation over time.

Benefits: maximum torque, optimised efficiency, synchronised speed, reliability.

Note: Our competitors only have one or two powered rollers as standard.

02

Special architecture: design for identical roller diameter

To guarantee the best performance in terms of bending and deformation of the part, we have four rollers of similar diameter.

The benefits: perfect geometry in the bending profile and better machine capacity.

Note:Our competitors’ lateral rollers have much smaller diameters -> reduced capacity

-> up to 30% additional bending.

03

Linear guide system

An incredibly useful technology, with no friction and excellent performance in all operating modes: cylindrical and conical rolling. It’s also a strategic choice for optimised prebending (on three- and four-roller machines)

Benefits: maximum efficiency of the hydraulic power, no wear.

Note: The planetary guide system used by our competitors is a low-cost solution

-> up to 30% loss of power and additional wear.

04

Bronze Bearing Technology

All of our machines are equipped with bronze bearings that accept high loads during rolling operations.

This technology is unrivalled in terms of both its capabilities and its longevity! Greasing is centralised and requires no maintenance.

Note: Our competitors use roller bearings (more economical, but unable to withstand heavy loading).

05

Strategy and smart management of clamping rollers

The lower roller has pressure and position control. This ensures a suitable clamping process to minimise deformation of the material.

Note: our competitors use pressure only, which often leads to lamination of the sheet and poor geometry

06

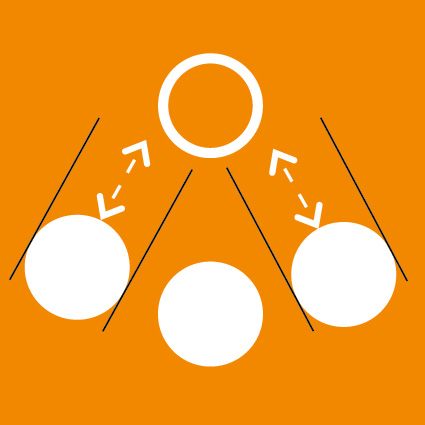

Three-roller operation

You can use your machine in three-roller mode to take advantage of its features.

Double prebending symmetrical configuration: for thin materials – symmetrical rolling for a tight tolerance – calibration of parts – calibration of welded parts.

Note: Feature not available from our colleagues because they have only one or two powered rollers.